Specialists in Industrial Plant Automation Systems

Specialists in Industrial Plant Automation Systems

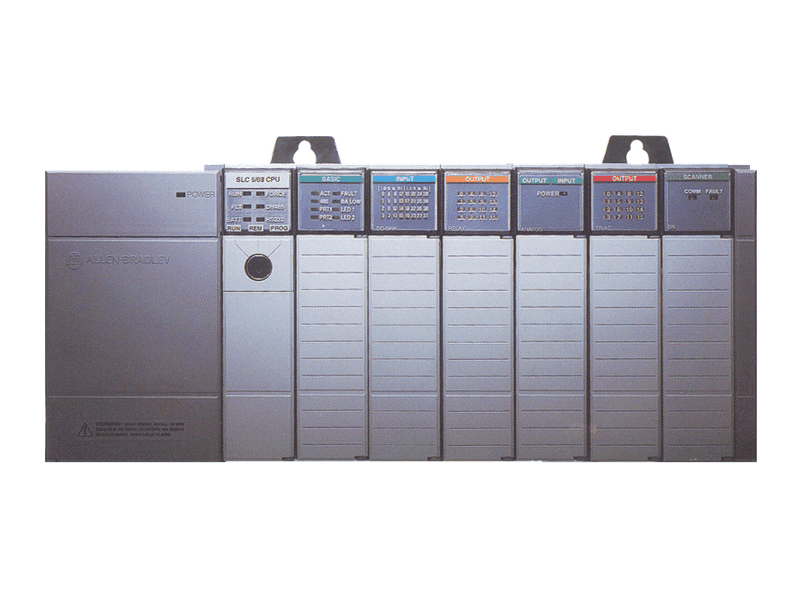

This course introduces the RSLogix 500 Programming Software. A system overview of the Rockwell SLC500 PLC, which includes hardware & software components, plus system configuration issues. The course concentrates on the ControlLogix PLC hardware, & troubleshooting. RSLogix 500 software diagnostic tools & programming instructions are introduced in the course to guide the delegate through the management of a realistic application.

The course consists of instructor-led tuition & discussions which focuses heavily on examples from the delegates own applications, backed up by practical hands-on sessions. Demonstration exercises are included & allow delegates to practice tasks such as testing, debugging & fault finding using diagnostic tools. Programming theory is kept to a minimum, the course is hands on with great emphasis on the practical aspects of Programmable Logic Controller application. The course is based around the Rockwell SLC500 PLC.

• Identify the components & performance characteristics of the Rockwell SLC500 PLCs

• Install a PLC system, including the communication cabling & wiring of I/O

• Operate the RSLogix 500 software to make it perform certain tasks.

• Perform system diagnostics when a problem occurs.

• Debug hardware problems

• Document, test, & troubleshoot an application program.

• Replace ControlLogix PLC hardware & modules when a fault occurs.

• Understand basic instruction set & be able to make minor modifications to software.

• Backup & restore a PLC program when required.

• Utilise binary operations, timers, counters, comparators, & arithmetic operations for modifications

Let’s discuss a training solution that fits your systems, goals, and schedule.

1. PLC System Overview

2. Programming Software

3. RSLogix 500 Software

4. Program Monitoring

5. PLC Program Elements

6. Configure & Parameterising the PLC

7. Diagnostics

We use cookies to improve your experience on our site. By using our site, you consent to cookies.

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Google Tag Manager simplifies the management of marketing tags on your website without code changes.

You can find more information in our Cookie Policy and Privacy Policy.